PAL 0 – ACTAS

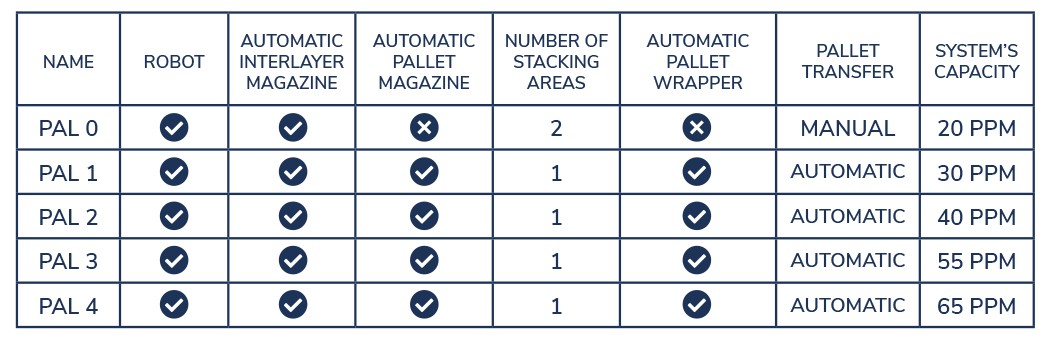

A semi-automatic palletizing line is characterized by a simple, least complicated structure of the palletizing cell, while achieving satisfactory production efficiency. This kind of robotic palletizing requires assistance of an operator.

The industrial robot, positioned in the center of the system and equipped with a row gripper, allows for ergonomic distribution of packages to one or two stacking stations. Centering devices (mounted to the floor) precisely determine the placement of the pallet, minimizing the time required for pallet exchange. The presence of the pallet is monitored by a sensor system.

The row gripper handles both bundles and cartons. The maximum weight of the handled goods is 80 kg. A set of three input conveyors feeding products into the palletizing cell enables their counting and preparation of an appropriately sized package for retrieval by the gripper. This system of factory palletizing can be equipped with foldable suction cups (mounted directly on the gripper) and a divider magazine, which allows for a more stable pallet arrangement.

A kicker, mounted to the side of the entry conveyor, enables the rotation of packages during entry, increasing the number of possible product configurations and maximizing the utilization of the entire pallet surface. The compact external enclosure, equipped with locked safety doors, protects operators from intentional or accidental access to the robot’s work area. Entry into the cell (e.g., for pallet exchange) is possible after pressing a button.

After completing the work cycle, the system allows access by electronically disconnecting all movable parts of the line. PAL 0 system can be equipped with a semi-automatic stretch wrapper placed in the most convenient location for the operator.

Semi-automatic palletizing lines by TES work for oil palletizing, frozen food palletizing, cheese palletizing, beer palletizing, water palletizing, soda palletizing and many more. Read on to find more about some of our projects based on the PAL 0 system.

Actas

One of our projects involved creating a palletizing system for a producer of vinegar. Our client ordered an end-of-line solution to palletize glass bottles in cardboard boxes. The line was designed to handle container volumes of 0,5l and 1l. During operation, a robot fitted with a fork gripper picks up to 3 boxes at a time and stacks 4 layers on a sigle pallet. With 2 stacking places used interchangeably, a complete pallet can be picked up by the operator, while another one is being loaded. A new, empty pallet has to be put in place manually as well. As a result, palletizing capacity of 10 cartons per minute was achieved.

PAL 1 – WYSOWA ZDRÓJ

Automatic palletizing equipment PAL 1, PAL 2, PAL 3 and PAL 4, due to its extensive pallet distribution system, allows for increased work efficiency and relieves operators of their tasks. This kind of robotic palletizing doesn’t require assistance of an operator.

The pallet magazine, with a maximum capacity of 15 EURO/CHEP pallets or 30 DHP pallets, can provide several hours of uninterrupted operation (depending on the line’s capacity) without operator intervention. Sensors installed on the magazine will notify the operator in advance when the container needs to be replenished. The roller and chain transport system will capture the pallet from the magazine, transport it, and center it in the palletizing area. The option to position the robot above the rollers or on a separate pedestal allows for adaptaing to any production line and eliminates unnecessary movements during operation. This way, stacking goods on a pallet is even more efficient.

The automatic stretch wrapper, placed in the pallet transport line, wraps the pallets with stretch film at a capacity of up to several dozen pallets per hour.

Similar to the PAL 0 solution, this factory palletizing system includes a standard modular/roller entry conveyor system, a gripper adapted to the handled product, and an optional separator magazine. The palletizing enclosure has been expanded to include an additional cell that allows access to one of the cells without affecting the operation of the other (adding separators without affecting the wrapper’s operation or replacing stretch film without affecting the palletizing process).

The setup is complemented by light curtains that, when connected to the safety circuit, protect access to the cells while allowing pallets to pass between them and the exit of finished pallets to the designated pickup area for the operator.

Complete production automation systems by TES will improve stacking and palletizing goods in your factory. Our machines are indispensable for palletizing beverages, e.g. beer palletizing, water palletizing, juice palletizing, as well as, oil palletizing, frozen food palletizing and even cheese palletizing. Read on to find out more about some of our projects based on the PAL 1/ 2/ /3/ 4 systems.

Wysowa Zdrój

End-of-line solution for Wysowa Zdrój Zdrój company is based on PAL 1 system. This producer of mineral water needed a palletizing system for 0,5l, 0,7l and 1,5l PET bottles, shrink wrapped in bundles (6 and 12-packs). During palletization, automatic magazine dispenses pallets which are transferred by roller conveyors right under the robot pedestal. Then, the robot equipped with friction gripper stacks layers of product, placing interlayer sheets in between. After picking up the bottles, the gripper can either release a full row of bundles at once or in two stages, arranging the second half of bundles accordingly. Stacking takes place on the conveyors, so when all 6 layers are in place, the pallet is transferred to the wrapping station within the same line. After being released from an automatic pallet wrapper with rotary arm, the palletizing process is complete.

Our clients usually choose standard palletizing solutions for their food, beverage or detergent processing lines. Depending on the size, weight and type of bulk packaging, our standard palletizing systems will handle carton trays, carton boxes, foil wrap bundles or plastic crates. TES palletizers are designed to be universal and therefore handle different types of containers – be it TETRAPACK palletizing, cans palletizing, PET bottles palletizing, glass bottles palletizing or jars palletizing.

Important features of TES collective packages palletizing include:

• Handling packs of any size, in varied batches

• Freedom in configuring the pack arrangement on the pallet

• Handling round, oval and irregularly shaped containers

• Possibility of handling several product types on one palletizing machine

• Easy retooling between the handled pack sizes

• Possibility to prepare and transfer a whole layer of products

• Original solution for feeding interlayer sheets

• Suitable for EUR, DHP, CHEP pallets