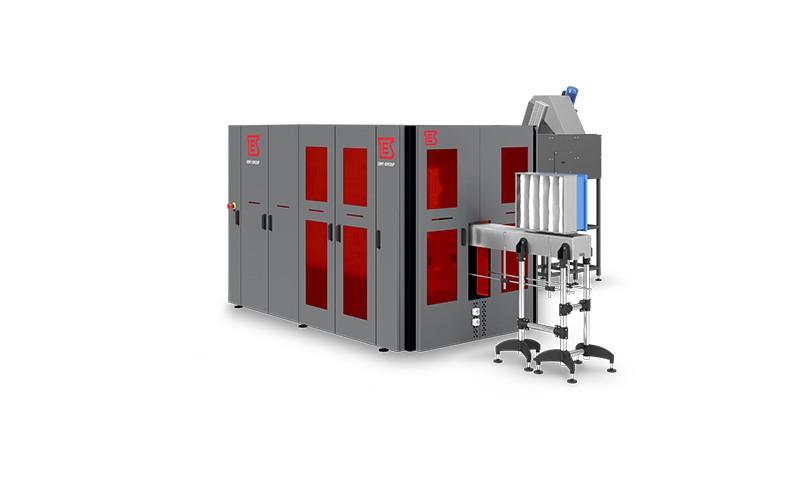

HOT FILL Series

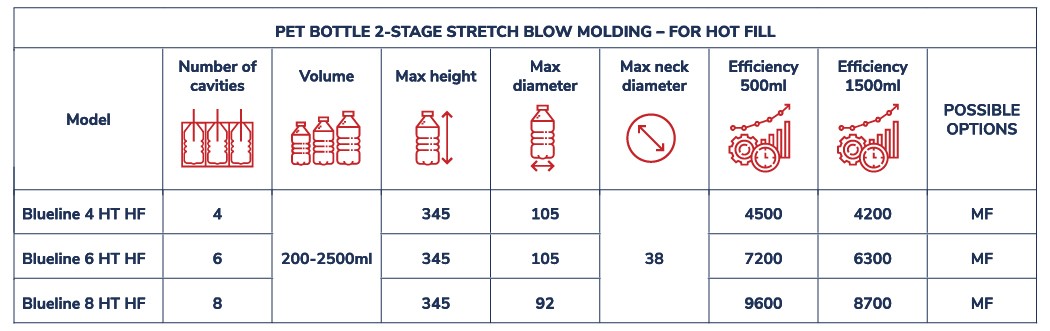

PET technology designed to handle hot liquids up to 88°C will be a perfect solution to complement your juice or iced tea filling line! As some products need to be preserved by high temperatures, TES offers highly-specialized blowing machines with MultiFlex as optional feature. Like all Blueline blow moulding equipment, HOT FILL machines are fully automated and electric. You will be able to manufacture PET bottles of 200 – 2500 ml volume. And capacity? With these blowmolders you can expect an output of 4200-9600 bph. Look at the three available models and choose the one that meets your production requirements.

You are free to choose any bottle shape you like. During PET blowing, the preforms are heated up in molds in order to assure proper sturdiness of the container. As soon as the bottles are released from the PET blow moulds, they are cooled by water. The PET bottles are treated with cold water before, during and after filling. What’s more, liquid nitrogen application prevents PET containers from deformation during the cooling process. All of this is achieved without compromising the low weight of the bottle.