Standard Solutions

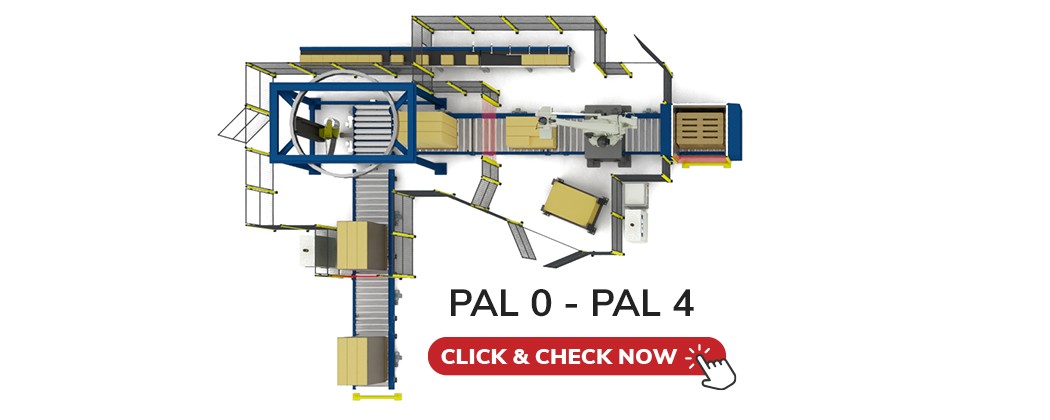

• Semi-Automatic Palletizer: PAL 0 – 20 ppm

• Fully-Automatic Palletizer: PAL 1 – 30 ppm/ PAL 2 – 40 ppm/ PAL 3 – 55 ppm/ PAL 4 – 65 ppm

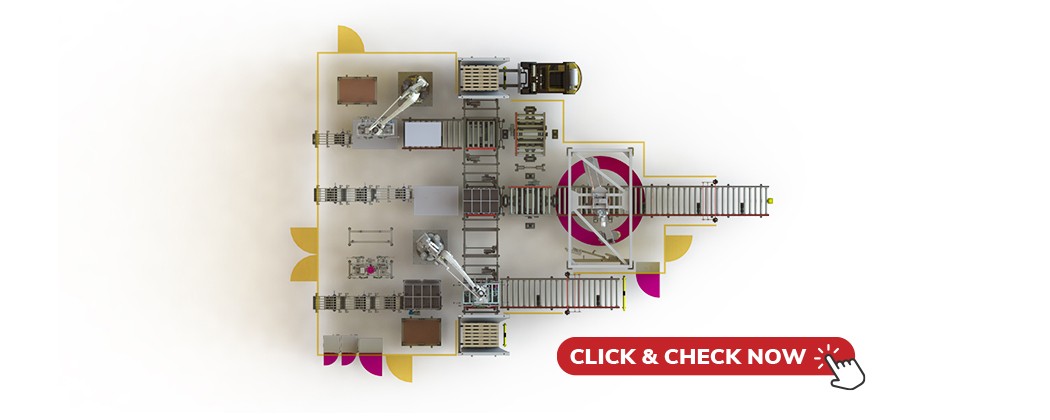

Special Solutions

See our custom-made projects:

• Palletizing System on 2 robots with 4 functions

• Palletizing System for very light and unstable 5-litre bottles

• Palletizing system for empty PET bottles

TES palletizing line is a fully automatic set of devices capable of picking a carton or a product from a high or low level and palletizing at one station or several separate stations in case of palletizing products fed from several separate packaging lines. The devices of the TES palletizing line will place your products on a pallet, then stiffen it and prepare it for transport by wrapping it with stretch foil. Importantly, our solutions will be also appropriate for soft products palletizing.

We offer several of our palletizing systems, which we have refined over the years, making them simple and proven solutions for rapid production automation. Such optimization is possible at any stage, even in an existing line. Our machines will handle frozen food palletizing, cheese blocks palletizing, battery palletizing or oil palletizing.

Standard systems we offer can be developed in the future from a semi-automatic solution into a fully automatic one – including storage, film wrapping and pallet transfer, which will further automate production on the line and minimize the number of staff required, ensuring the highest quality and repeatability of the palletizing process at the same time. TES is official integrator of Kawasaki robots.

In our simplest palletization, the operator has to deliver empty pallets to two stacking locations, deliver the interlayer sheets to the divider warehouse and, once the product has been palletized, take the pallet to the free-standing pallet wrapper and on to the warehouse, as well as deliver another empty pallet in place of the one that has been collected.

More sophisticated systems require only delivery of stacked empty pallets (10pcs), adding interlayer sheets and collecting wrapped pallets. With such an automation, the same single operator is able to handle the end of the line with a much higher capacity.

Based on the product, we select an industrial robot suitable for your needs (Kawasaki, Kuka, Fanuc, ABB):

• Kawasaki CP 180 or equivalent – 180 kg (PAL 0/PAL 1) – Row gripper (bundles)

• Kawasaki CP 300 or equivalent – 300 kg (PAL 0/PAL 1) – Row gripper (cartons)

• Kawasaki CP 500 or equivalent – 500 kg – Used for more complex configurations – preparation of the layer is required

After stacking goods on a pallet successfully, it’s time for stretch wrapping. TES offers wrappers for small, medium and high efficiency:

• Semi-automatic wrapper – Its efficiency is dependent on operator’s work.

• Automatic turntable stretch wrapper – Its maximum efficiency goes up to 35 pallets/ hour.

• Automatic wrapper with rotary arm – Their efficiency is estimated at 40 pallets/ hour.

• Automatic wrapper with rotary ring

Designing process automation in your smart factory does not end here yet. During collective packages palletizing one has to take into account several important factors:

• Top Pressure – It will be required for palletizing lightweight products that may be displaced during arm rotation.

• Electronic Prestretch – Economical use of film, adjustable stretching during the wrapping cycle. It may eliminate the need for top pressure.

• Pallet Lifter – Necessary for wrapping the product together with a portion of the pallet, as this affects stability during transport.

• Easylock – If a pallet lifter is not available, it stretches the film, allowing the product to be wrapped with the pallet without lifting it.

• Topsheet – Additional layer of film applied on top of the pallet to increase its tightness.

The final performance of the palletizing line can be estimated after providing preliminary data. Depending on whether you need bulk palletizing, bags palletizing or carton boxes palletizing, the efficiency will vary accordingly.