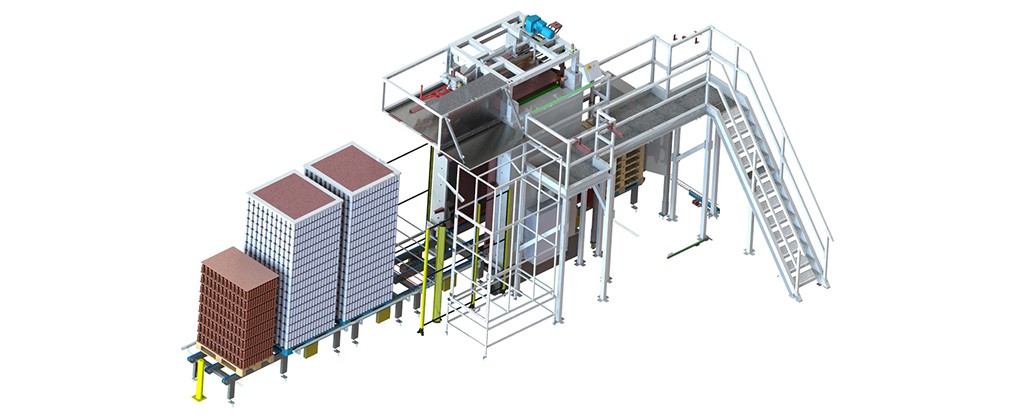

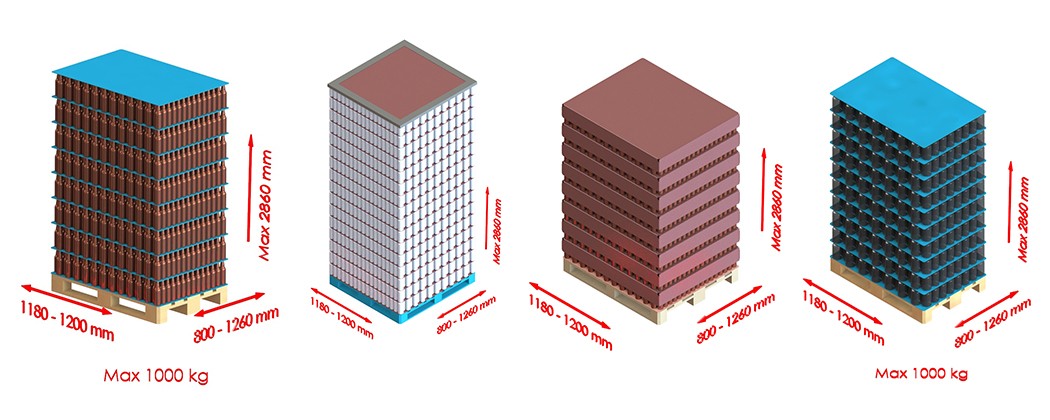

Depalletizing usually takes place at the beginning of the production line. TES depalletizing machines carry out high-level unloading of empty containers, like: aluminum cans, glass bottles, jars and other containters. This dedicated device can handle full pallets weighing up to 1200kg. What’s more, one machine is versatile – it is able to handle bottles depalletizing, cans depalletizing or jars depalletizing.

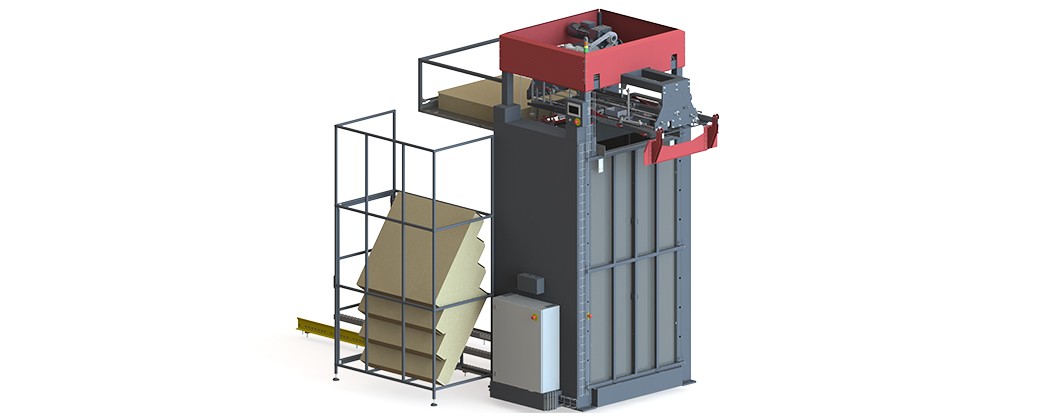

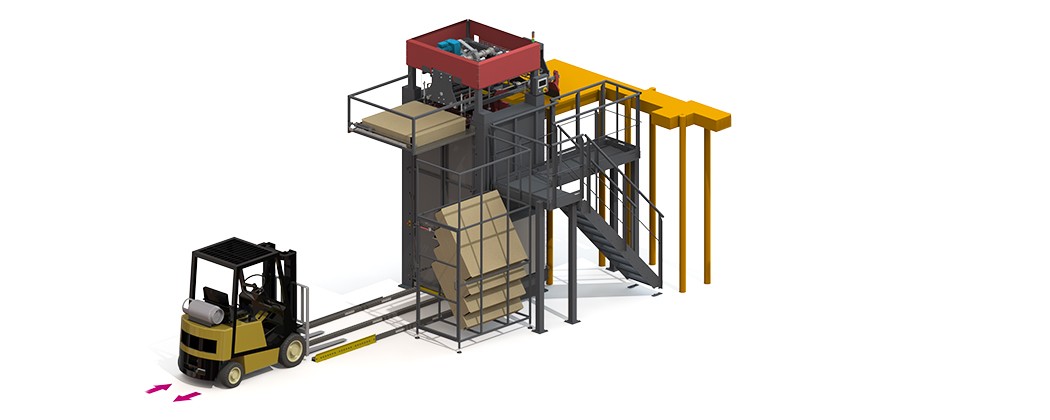

Depalletizing process starts with transporting full pallets by a forklift or hand pallet truck, depending on the chosen type of depalletizer inlet. Before entreing the the elevator, the pallet must be prepared. The operator has to cut and remove the film wrapping the pallet and the tie straps. Next, one can insert the pallet into the loading bay, then, close and lock the two-leaf doors. Depending on the product you want to unload, you will have to select the appropriate recipe from the HMI. The pallet is lifted until the first layer is detected by the height sensor. After that, cardboard interlayer sheet is removed from the top of each layer. Then, containers are pushed onto the buffer conveyor. When empty, the pallet slides down and is then is transferred out of the depalletizing unit, for example, to the optional empty pallet magazine.

Your depalletizer can come in different variants and additional parts may be added to ensure smooth operation of the system. Nevertheless, whether you need to unload layers of glass containers or aluminum cans, the core elements of a depalletizing line include:

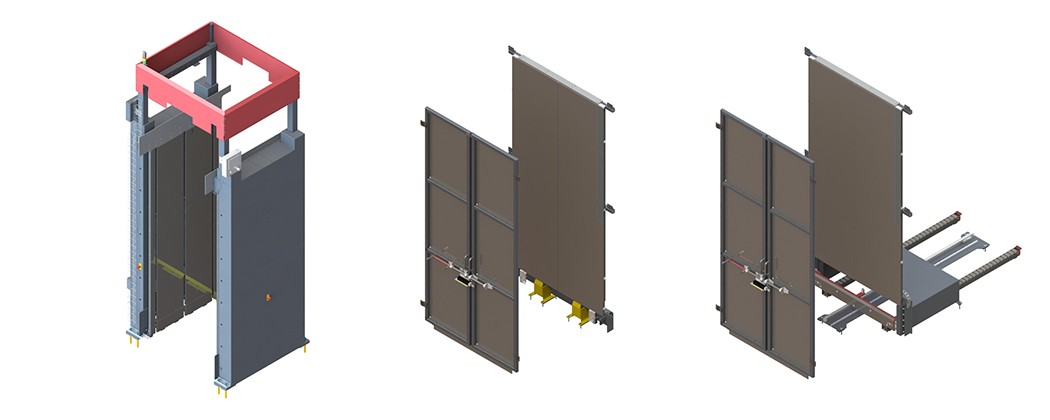

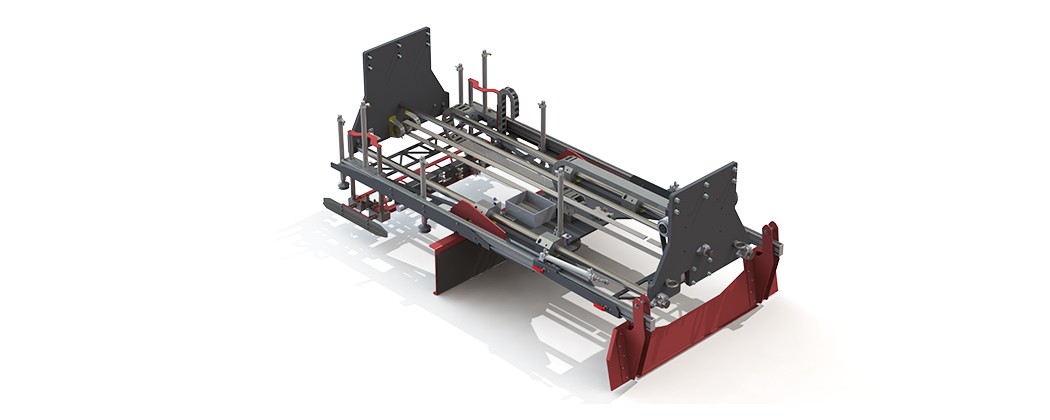

• Frame – It is positioned at the centre of the depalletizing machine. It serves as the load-bearing structure for most components. In the basic version, the rear wall is fitted with a ground anchored bumper that positions the pallet during insertion. In a fully-automatic version, it allows the pallet to be removed from the depalletizer by means of a retrieval system.

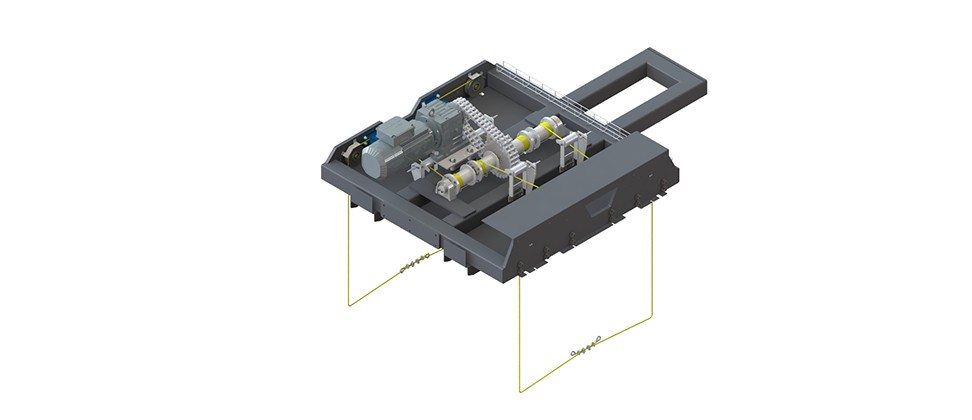

• Drive Train – Mounted on top of the depalletizer, it lifts the loaded pallet. It consists of a system of ropes, pulleys, and cable drums driven by a geared motor.

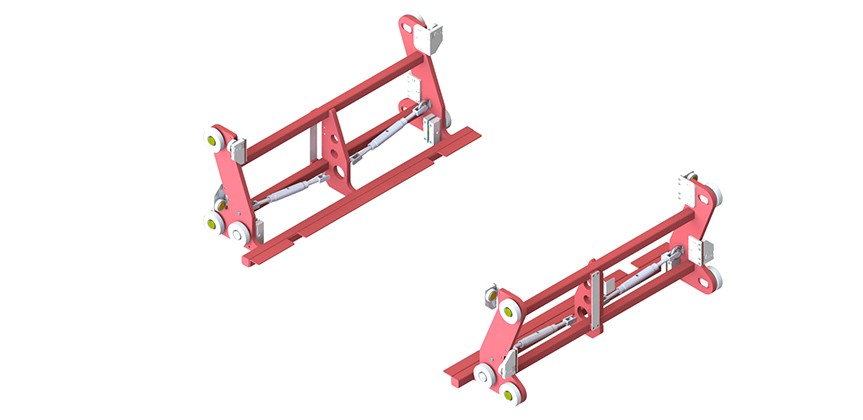

• Lift Beams – Suspended on ropes inside the depalletizing machine, they are the executive element that raises the pallet. The lift beams can handle full pallets weighing up to 1200kg.

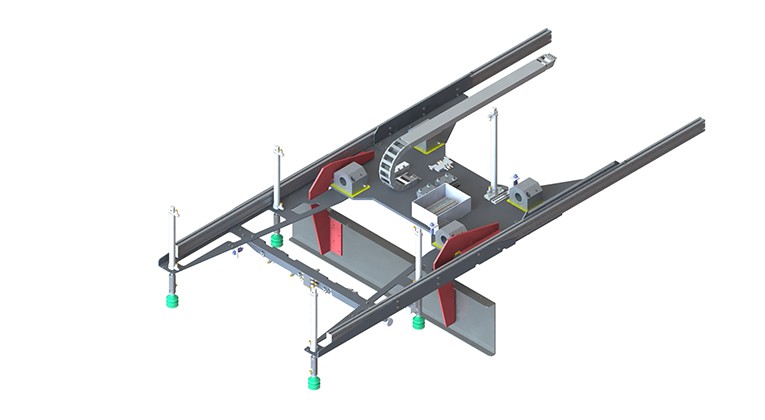

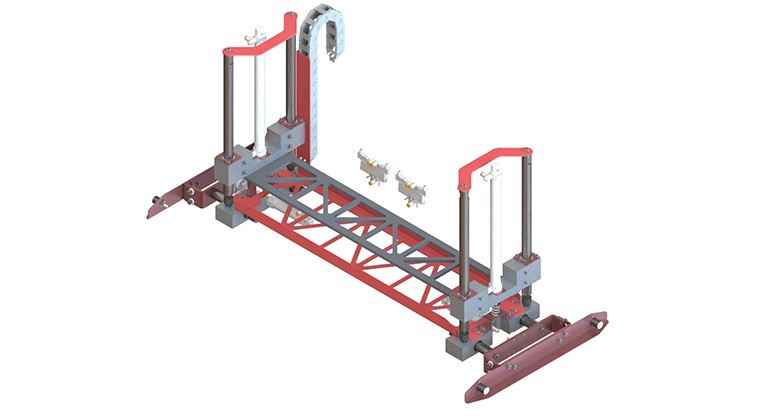

• Pusher with Divider Pick Up – The role of this system is to push a layer of containers onto a conveyor. The device is fitted with a sensor that detects the top layer of the handled pallet. Before that, a set of 4 vacuum grippers automatically picks up and transfers interlayer sheets aside so they later can be automatically moved into a dedicated storage.

• Container Holder – Installed opposite the pusher, this device additionally secures empty cans, bottles and jars against tipping over, while thay are being pushed off the pallet onto the conveyor.

• Divider Magazine – One more depalletizer feature TES offers, is designed for discarding interlayer sheets. They are placed onto a divider dump and when completely filled, the interlayer sheets are moved by the pusher to the divider storage.

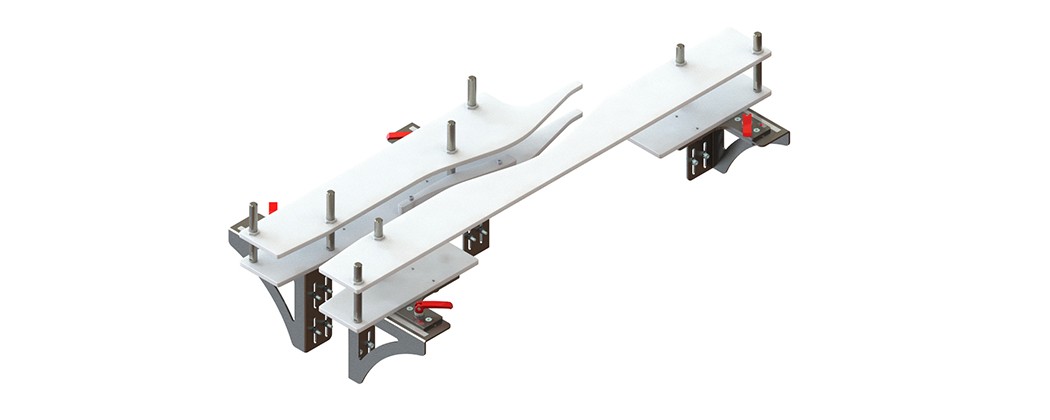

• Container Conveyors – They are located between the main depalletizing unit and the bottling line. The set is comprosed of 3 sections: buffer conveyors, intermediate conveyors and liner conveyors. Their purpose is to arrange an entire layer of containers in one row, allowing them to be further transported to the bottling machine or can filling machine.

• Vertical Conveyor (lowerator) – is located downstream of the liner conveyors. Designed to transport containers from high to low level. Rubber pick-ups ensure safe a firm grip and are easy to set up for different-sized bottles or jars.

• Operator Platform – positioned along the main unit and product conveyors. It provides access to the upper part of the depalletizer and is equipped with operator’s panel, which allows for changing operation settings of the machine. The platform allows for manual removal of the top frame with special mounts for safe deposit.

Available Options

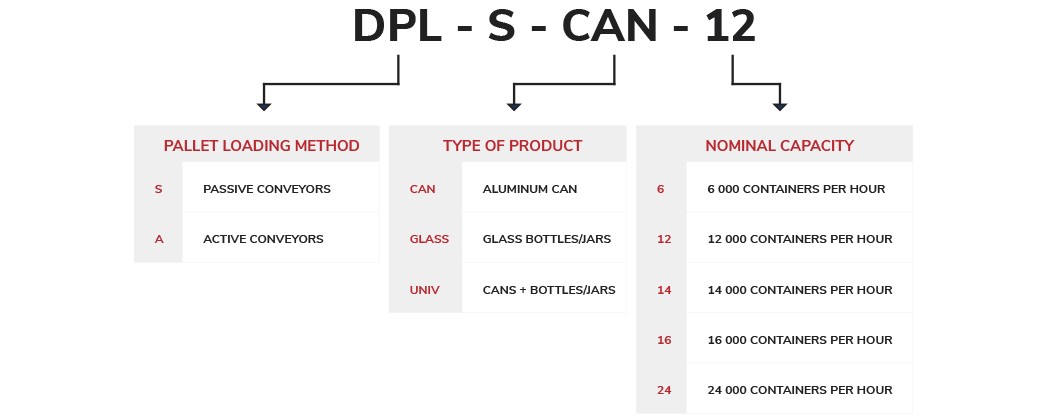

For full automation and depalletizing efficiency more features can be implemented. To note, the depalletizing system may be designed specifically for aluminum cans, glass bottles or as a universal solution for both.

Installing conveyors at the beginning of the line facilitates the loading of the pallet into the depalletizer. Located right in front of the passive roller conveyors, a centering section will ensure appropriate positioning of the pallet. Another option, automatic chain conveyors will serve as an extra buffer area where the pallet can be prepared before entering the line, especially in the high capacity filling lines.

One thing to remember, depalletizing capacity varies depending on the option chosen. For manual loading, you can expect efficiency up to 55 layers per hour (bottle depalletizing) or 65 layers per hour (can depalletizing). Estimated time of pallet exchange by the operator is less than 120 seconds. For automatic loading, you can expect depalletizing efficiency up to 67 layers per hour (bottle depalletizing) or 73 layers per hour (can depalletizing). In this case, the pallet is inserted in the depalletizer by automatic chain conveyors.

Dedicated Solutions for Cans

The process of depalletizing cans in your factory will require removing the protective metal frame located on top of the pallet. After unloading all of the layers, it will be deposited on an empty pallet. Liner conveyors for cans end with a twist rinser which cleans the inside of the cans on their way to the filling machine level.

Dedicated Solutions for Glass Bottles

For glass bottles depalletizing, you can expect TES to install a container dump in your technological line. Guiding cams ensure that an overturned or skewed bottle is removed before entering a vertical conveyor. What’s more, vertical conveyors can be fitted with an air rinser, which cleans the inside of the bottles while overturning them before they get to the filler (i.e. in case of oil filling, when there is no rinser installed).

Since launching first TES depalletizing system, we have introduced many improvements to our production automation solutions. The upgrades include:

1. Replacing sliding rear wall in the frame by a fixed one. While maintaining stable grip during depalletization, we were able to reduce gaps between the steel plates – especially in the corners of the inner walls.

2. Increasing the number of cable drums from 2 to 4. This change allowed for easier manipulation of pallet position and relieving weight distribution on vertical forks.

3. Adding extra container holder for pushing the products onto the conveyor – for more secure and steady transfer.

4. Replacing induction sensor with encoder for more precise and flexible control of the depalletizing process.

5. Automatic pick-up of metal frame securing top layer of cans on a pallet – no need for an operator to manually remove it.

6. Adding extra components for seamless entering of the pallet, like: passive roller conveyors, centering unit and transfer pallet (made of metal) serving as a base for non-standard sized pallets.

7. Increasing security of the depalletizing process by adding fully enclosed sides to the divider dump – protection against plastic and cardboard interlayer sheets falling.

TES delivers depalletizing systems all over the world. Thanks to our expertise we are able to design depalletizing line for every type of pallet size and container – whether our client needs a depalletizer for cans, bottles or jars.

Depalletizing for Racibórz Brewery – Poland

Capacity:

• 0,5l cans at 5000 cph

• Pallet size: 1250×1180

• 0,33l cans at 6000 cph

• Pallet size: 1250×1180

• 0,5l glass bottle at 3000 bph

• Pallet size 1200×1000

Depalletizing for Połczyn Brewery – Poland

Capacity:

• 0,5l glass bottles at 5500 bph

• Pallet size: 1200×1000

• 0,33l glass bottles at 5500 bph

• Pallet size: 1200×1000

Depalletizing for Daruvar Brewery – Croatia

Capacity:

• 0,5l cans at 14 000 cph

• Pallet size: 1265×1180

Depalletizing for Szatmár Íze Biró – Hungary

Capacity:

• 0,25l cans at 6000 cph

• Pallet size: 1245×1175

• 0,22l – 0,72l glass jars at 5000-6000 bph

• Pallet size: 1200×800 & 1200×1000