At TES we specialize in production automation and robotization. As an engineering company, we are able to design and deliver turnkey robotic palletizing systems for your manufacturing plant. Apart from our standard palletizing solutions , we offer custom palletizers. Sometimes our clients need unusual machines which can handle empty bottles palletizing, bags palletizing, palletizing of cheese blocks, palletizing of fragile cargo or loose goods palletizing, e.g. stacking individual bottles on a pallet.

Check out our portfolio of some of the unique palletizing systems we implemented. If you are interested in detailed project estimation and design, contact us here.

1. Palletizing Car Batteries for Excide

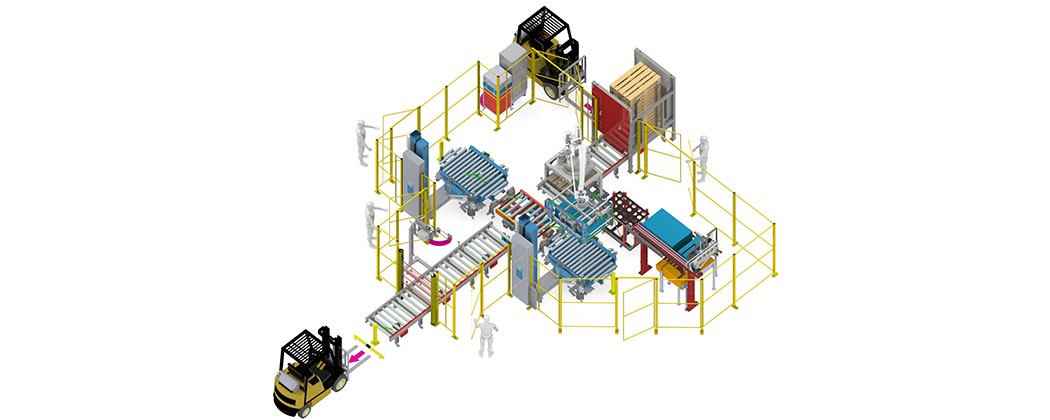

This palletizing system handles 4 different product feeding lines of different efficiency. Production lines cumulate in central palletizing system where 2 robots stack batteries in a continuous mode. Each robot handles 2 lines at a time and stacks products on 2 palletizing stations. The robots work simultaneously, handling batteries of different volumes (from 175×175 to 275×520 mm) and weight (from 10 to 63 kg). One robot has the capacity to palletize 840 small car batteries or 360 big truck batteries per hour.

Universal gripper adapts to varying sizes of an individual car battery. The device is able to pick 1, 2 or an entire row of products, as required by desired arrangement. Gripping combinations allow for 5 different product setups. Complex arrangement of products on a pallet was achieved thanks to adopting orienting machine, ranging from 7 to 17 items on a single layer. Depending on the weight of the layer, appropriate divider is used.

CAR BATTERIES PALLETIZING:

TRUCK BATTERIES PALLETIZING:

This palletizing line synchronises many components: pallet magazine, dividers magazine, wrapper, labeller, transport systems with turntables, conveyors equipped with orientating machines and centering mechanisms for batteries. What’s more, the palletizing line is divided into 3 cells – robot maintenance or wrapper maintenance can be carried out without disturbing other stages of production.

2. Palletizing Meat for StarMeat

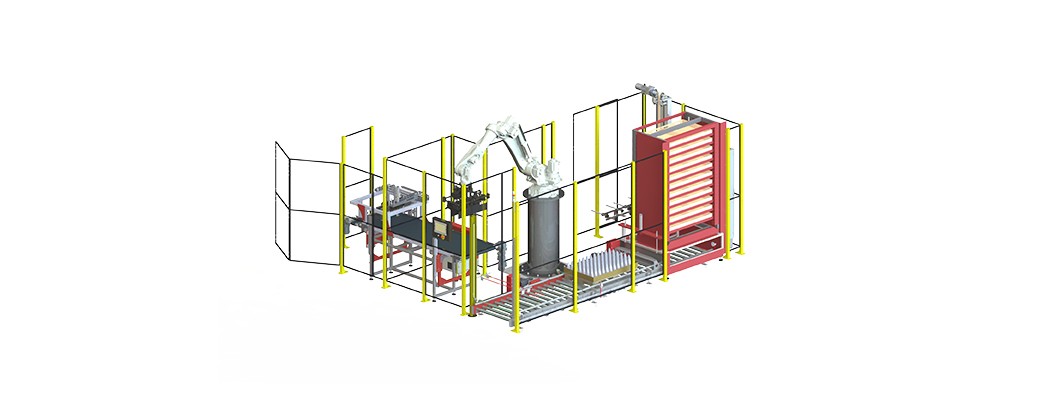

Palletizing blocks of meat was a challenging project due to increased hygiene requirements and irregular size of the products. Meat blocks were often undersized or oversized. This resulted in uneven layers with the product either sticking out or leaving empty spaces between individual pieces.

We solved this issue by installing system for retooling, allowing to verify the appropriate size of the block. We applied weighing and X-Ray devices detecting udesirable items. Those exceeding the average proportions are manually taken care of by the operator. Additionally, it’s possible to use vision systems recognizing product arrangements and their defects.

Peripheral devices in this palletizing line include: a 4-axis robot, a wrapping machine, a labelling machine and a weigher. The system achieves efficiency of 1 block of meat per 4 seconds, with each layer containing 4 blocks. Next, each layer is covered with stretch foil – a solution TES designed from scratch – allowing to prepare up to 17 layers stacked on one pallet, with palletizing efficiency of 900 blocks per hour.

3. Palletizing PET can preforms for Esterform

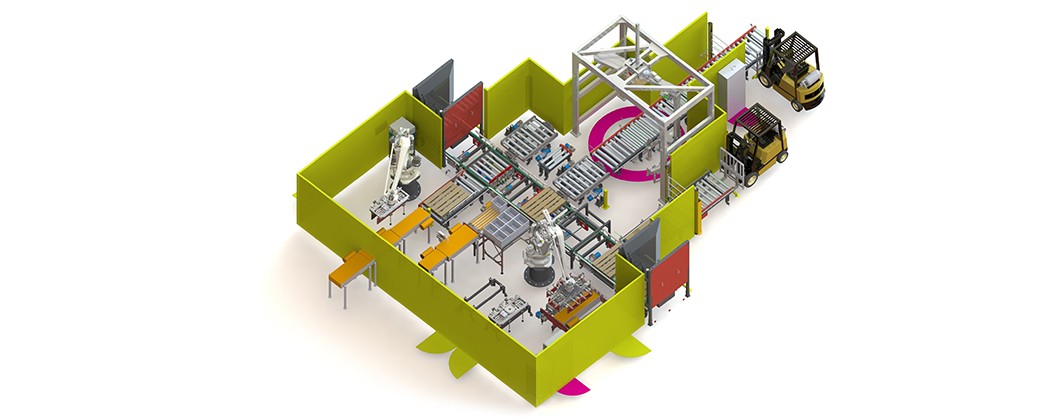

TES created compact dedicated solution for automated collection of preforms from the injection moulding machine and their palletization. Both, the injection moulding machine and the palletizing robots are fully integrated. The system combines 2 robots working together in one cell, which are protected against collision. What’s more, the palletizing robot is placed on linear rails to minimize working area.

The manufactured items from the machine are fed through automatically controlled door. The first robot collects the items from the injection moulding machine and places them onto a table adjusting the layout of preforms. Then, the arranged preforms are picked up by another robot and placed on the client’s trays. Since PET cans preforms are lightweight, they are handled by vacuum grippers.

The palletizing line is equipped with turntable tray magazine – a reliable solution, used in many other TES projects. The automatic magazine can be restocked while the robots are operating, maintaining steady capacity. To note, it also allows for picking the trays from the same place and height – it allows for less complicated robot movements and gripper design. Additionally, the tray magazine is equipped with an inspection drawer, where an operator can manually carry out quality control.

After feeding the tray and with preforms in place, they are taken to one of 2 palletizing stations. With automatic measurement of stack height, completed pallets can be picked up without disturbing the process. At any point, the client can upgrade the system with an automatic pallet magazine, wrapping machine and other technical solutions.

4. Palletizing loose 5-litre PET bottles for Masspol

This client ordered a complete water filling line based on synchroblock. As a part of STM Group, TES was tasked with designing and manufacturing the end of the process. The project was customized to accomodate for very light and unstable 5-litre bottle, which is taller and narrower than a typical bottle of the same volume. This original design allowed for increasing the number of bottles on a pallet – from 108 to 162!

The palletizing process starts from in-line bottle divider, which delivers 2 rows of bottles to the layer preparation system. In order to prepare the layer, rows of 6 bottles are pushed onto a belt conveyor until all 54 bottles are lined up. Next, the layer is transfered by a roller gripper. To optimize the time of layer stacking, the gripper was equipped with vacuum grippers to pick up interlayer sheets at the same time.

Pallet warehouse stores 15 EURO pallets and feeds individual pallets automatically. Empty pallets are trasferred by turntable roller conveyor to one of 2 stacking places. Since the 5-litre bottles were not packed in bulk in shrink foil, wrapping stations are integrated with stacking places. As full pallet transfer is eliminated, 2 rotating plate wrappers secure the stacked layers. With efficiency of 4000 bph, the palletizing system meets the capacity of the rest of the line.

5. Palletizing empty PET bottles for Retal

Palletizing empty PET bottles comes with it’s own set of challenges. Engineers at TES had to take into account the unique properties of PET bottles coming straight from the blow molding machine, as opposed to ones that could cool down after the production process. Additionally, empty bottles proved to be extremely sensitive to weather changes, as minor as cross breeze. On top of that, each PET bottle has a slightly different gravity center – a fact which made this palletizing project even more demanding.

These unique conditions called for smooth and precise machine movements. We managed to design a very compact and scalable system, suitable for blow molding machines of different capacities. Adapting the palletizing system to existing line for PET stretch blowing we made sure it would handle bottles of different volumes and shapes – in this case, from 150 to 500 ml. Achieving the capacity of 5.000 bph, the palletizer works with 12 PET bottle formats.

Empty PET bottles are transferred by a long air conveyor to a layer preparation table. The bottle divider can be easily retooled, according to the type of container handled at the time. Depending on the size of the pallet and bottle format, the system counts and prepares a row of bottles to be transferred onto the table. During layer preparation all the PET bottles are secured by stabilizing rails on either side.

The palletizing robot is equipped with two types of grippers. Friction gripper transfers a whole layer of bottles onto the pallet. Next, vacuum grippers pick an interlayer sheet and put it on top of each stacked layer of bottles. A complete pallet is then transferred by roller conveyors to automatic strapping machine, which secures the layers with 2 vertical straps. Finally, the pallet goes to top pressure wrapper with rotary arm. The palletizing process is complete once the operator picks the wrapped pallet.

6. Palletizing system on 2 robots with 4 functions for Daruvar

This solution was designed for the 2nd oldest brewery in Croatia. Based on 2 robots, the palletizing system serves as the end stage for 3 independent production lines, filling beer in cans, PET and glass bottles. The challenging part was to manage pallets within the cell, as they were obtained from the pallet magazine, as well as from the depalletizing process. Secondly, we had to combine depalletizing and palletizing function in one robot.

The first step was to integrate the system with the existing filling line for returnable glass bottles at 20.000 bph. One robot picks 8 crates at a time, interchangeably depalletizing and palletizing crates (4×5). During operation of the glass line, pallets are used 1 to 1 – when de-stacking of crates with empty glass bottles is finished, the EURO pallet is moved to a palletizing station by chain transporters. Alternatively, it can be moved to the nearby pallet magazine.

The same robot can be retooled to handle packs of PET bottles. To make this happen, 2 types of detachable grippers were designed. They are put away on designated stands. What’s more, the changeover of formats takes 1 minute only. The operator’s task is to change an electrical plug, compressed air delivery and 4 clamps. The palletizing robot automatically repostitions from one gripper to another. The 2-litre PET bottles are palletized in 3×2 packages at 3000 bph capacity.

Second robot in the system exclusively handles can palletizing at 15000 cph. They come in packs of 6×4 (film + tray), 3×2 (film only) and 2×2 (film only). A single layer is formed either from 24-packs, while 6-packs and 4-packs are arranged together. When 8 layers are stacked, the pallet is transported to a top pressure pallet wrapper with rotative arm. The same wrapping machine is suitable for other products as well. To note, can palletizing line works independently, while the second robot works on either PET or glass line. Smooth operation of both robots is ensured by a buffer.

The whole system is fitted with 2 fully automated pallet magazines (for 15 EURO pallets each) – for stacking and de-stacking pallets, depending on the undergoing process. To note, each palletizing station has it’s own magazine for interlayer sheets. Big operator panels were added for convenience and efficiency. Apart from film and pallet replenishment, this palletizing system doesn’t need the supervision of an operator.