A stretch blow molding machine is an essential piece of equipment in mineral water production, edible oil production, milk production, juice production, detergent and chemical liquids production. TES blow molding machines are fully automatic and are designed for different bottle sizes and production capacities. If you equip your smart factory with PET technology from TES, you can expect:

• high efficiency (2000 bph from one cavity)

• low energy use (1,5W for 0,5 bottle)

• minimal maintenance time

• online monitoring

We currently offer linear blowing machines with efficiency ranging from 800 to 12000 bottles per hour. These stretch blow molding machines are a perfect choice for medium-sized manufacturing plants. Depending on the size of the PET container, we will suggest an appropriate blowmolder. Experts at TES will design your bottle and create PET blow molds – you can choose volumes as small as 10ml or as big as 12l. To note, apart from PET bottles, we produce our blow molding equipment for PET cans as well.

There are several types of blow moulding machines available. Choose the best option depending on your needs and requirements. Check out different series of blowmolders, including: STANDARD, HITECH, BIG, MAX, HOT FILL and CAN.

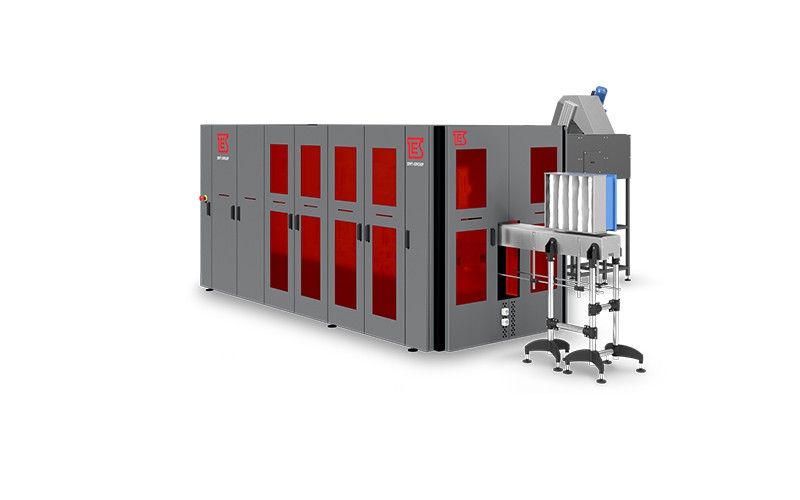

STANDARD & HITECH series

STANDARD series machines are based on pneumatics. These PET bottle machines are fitted with original solutions developed by TES: Eco Power Blowing System, Diagnostic System, Heating System and Streching System . Additionally, they can be upgraded with Air Recovery System . Choose from four different versions of the STANDARD type blowmoulder and manufacture containers of 200-2500ml volume.

HITECH series machines are based on servomotors. This series of blow molding equipment is fitted with all five Eco Power Innovation Systems as default. Select one of four versions of the blow moulding machine and produce PET containers of 200-2500ml volume.

BIG & MAX series

BIG series machines are available as STANDARD or HITECH versions. These blowmoulders are meant for bottle volumes of 1-6 litres. Select from four available versions of the BIG bottle blowing machine that meet your required capacity.

PET blow machines from MAX series can manufacture containers up to 12 litres – the largest PET bottle size in our offering. TES offers MAX blow moulding machines with three different efficiency levels, all based on a STANDARD framework.

HOT FILL series

HOT FILL blow molding machinery is resistant to liquid temperatures up to 88°C. You will be able to produce PET containers within 200-2500ml range. All three variants of the HOT FILL blowmoulder are equipped with HITECH solutions.

CAN series

Stretch blow moulding machines from CAN series manufacture PET cans which are later closed with an aluminum lid. Based on HITECH framework, this blowmoulder can manufacture containers within 200-1000ml volume range.

Each of our blow molding machines can be fitted with additional features. Available options for TES Blueline series machines include: MultiFlex, Preferential Heating, Deep Grip and Air Recovery System.

POSSIBLE OPTIONS FOR BLOW MOLDING MACHINES

MultiFlex

a system for easy retooling of the PET blowing machine, which allows to use many preform neck sizes. Once you change the mandrels, infeed starwheels and grippers, you can start producing PET bottles with a different neck diameter just within 30 minutes. It is particularly suitable for manufacturers of empty PET bottles, as one isn’t limited by one container neck type. MultiFlex system is comprised of two parts – adapting the machine for working with other threads and the extra format parts for retooling the blowmolder. That’s why at first you may simply opt for adapting your machine into MultiFlex version and later, when the time is right, you may purchase the neck formats that you are interested in. If you want your blow moulding machinery to be universal and versatile, it is an option to consider.

Preferential Heating

this feature was developed in order to produce PET bottles which are asymetric, oval or flat. More complicated shapes require different treatment and precise temperature control. Dring the blowmoulding process the preforms are fed through a heating oven. Interchangeably rotating faster and slower, preforms are treated with infrared radiation on a limited surface. With preferential heating system, your blowmoulder will produce a variety of packages without compromising their quality and aesthetics.

Deep Grip

a type of technology which allows to manufacture PET bottles with a clearly defined handle. This feature is commonly used for packaging chemical products and edible oil. Our clients usually choose this option for containers of 2-litre volume or bigger. Blowing molds are fitted with a piston, which is pressed into the PET container during the blowing process. As a result, we can precisely achieve the grip effect.

Air Recovery System

one of the Eco Power innovations designed for our blow molding machines. Available in HiTech machines as default setting, it allows you to recover compressed air during the process of blowmoulding. As a result, you can save 20-50% of air consumption. Other Eco Power solutions patented by TES include: Blowing System, Diagnostic System, Heating System and Streching System. The recovered resources can be used to power the PET bottle machine or other plant equipment. Sustainability is key in times when energy and supply costs are wavering. Thus, innovations developed by TES will make your business secure against unpredicted changes.

Check out different PET packaging our clients manufacture with TES stretch blow moulding machines:

At TES we will manufacture blowing molds for your original PET bottle. If you need help designing, you can count on our expertise in PET blow molds production.

Find out more, here: